AI in Mining Operations: Efficiency and Safety

AI in Mining Operations: Efficiency and Safety

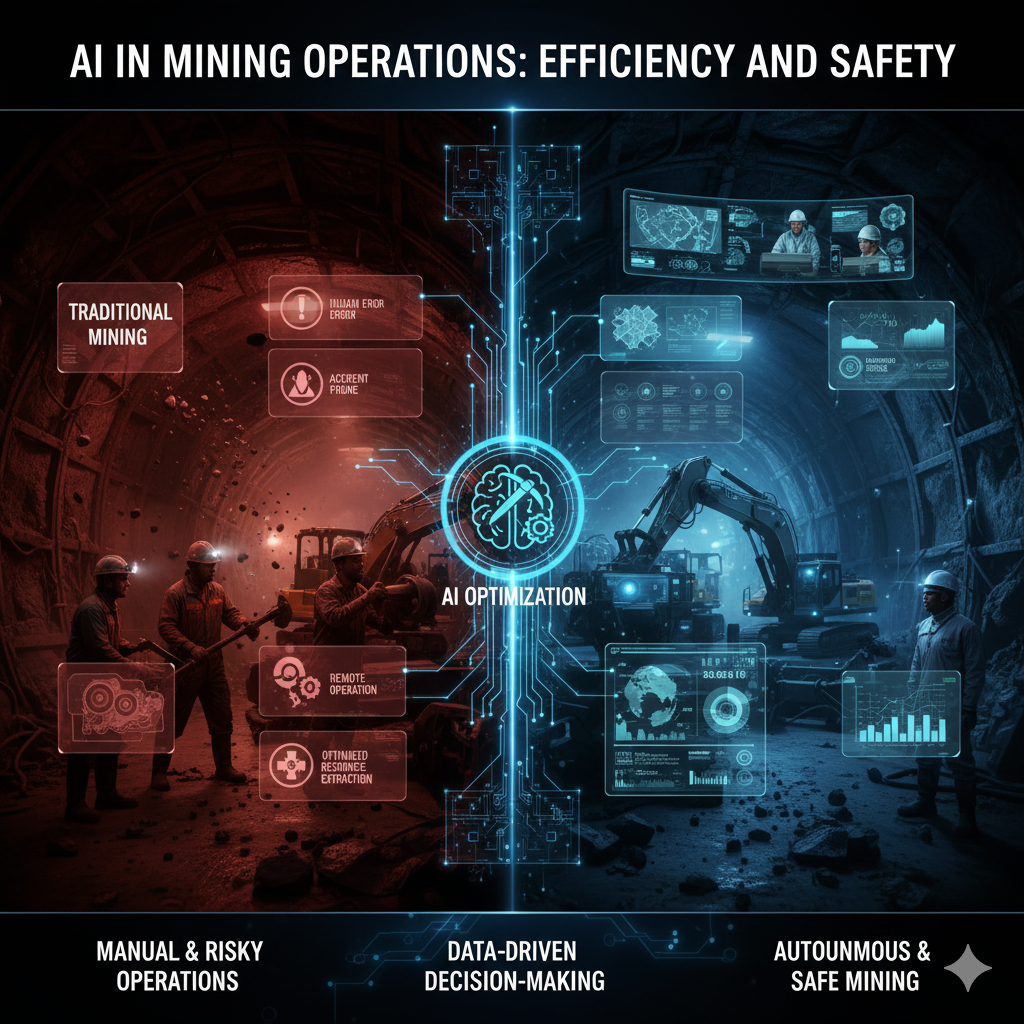

One of the businesses that is most dependent on resources and dangerous in the world is being revolutionized by the use of artificial intelligence in mining operations. In the past, the mining industry has relied on heavy machinery, manual inspections, and processes that require a lot of effort. These methods have often subjected miners to hazardous situations, including unstable terrain, poisonous gasses, harsh temperatures, and high-powered equipment. Artificial intelligence (AI) is the introduction of intelligence, automation, and real-time monitoring capabilities that significantly increase productivity, optimize resource extraction, and improve worker safety. Artificial intelligence is able to assist mines in operating with more precision, fewer accidents, and lower operational costs by evaluating massive amounts of operational data, forecasting hazards, and automating crucial operations.

Maximizing the Efficiency of Resource Extraction Utilizing Artificial Intelligence

Artificial intelligence (AI) systems examine a variety of data sources, including geological information, drilling records, sensor outputs, and mineral distribution maps, in order to ascertain the most effective extraction procedures. These models are capable of locating zones that are high in yield, optimizing the depth of drilling, and minimizing the amount of trash that results from over-extraction. Artificial intelligence (AI) is able to guarantee that a greater quantity of material is mined while simultaneously decreasing the amount of fuel that is used and the number of operational delays that occur by increasing the precision of mining patterns.

Improving the Efficiency of Equipment by Utilizing Predictive Maintenance Techniques

Equipment that is used in mining operations, including loaders, haul trucks, crushers, and drilling rigs, are subjected to very high levels of stress. The predictive maintenance system that utilizes artificial intelligence keeps track of the temperature, hydraulic pressure, vibration, and engine performance in order to recognize any early indicators of deterioration or malfunction. The use of artificial intelligence (AI) to anticipate equipment malfunctions before they happen results in less downtime, lower maintenance costs, and the prevention of accidents that are associated with malfunctioning machinery.

Enhancing the Safety of Employees Through the Use of Real-Time Monitoring

Hazardous situations are detected before they might worsen thanks to monitoring systems and sensors that are powered by artificial intelligence. Unstable terrain, gas leaks, the close proximity to hazardous equipment, and odd vibrations that might indicate the possibility of collapse are all included in this category. Supervisors are able to evacuate areas, make adjustments to operations, or promptly shut down machinery with the use of real-time notifications. The rates of injuries experienced by workers are considerably reduced by this proactive strategy, which also safeguards them from hazards that are not immediately obvious.

Methods for Automating High-Risk Tasks

Repetitive, hazardous, or physically demanding labor is a common feature of many mining operations. Tasks like as drilling, hauling, blasting, and ore sorting may be performed by autonomous equipment and artificial intelligence (AI)-powered robots. The likelihood of accidents and injuries occurring may be reduced by preventing human workers from entering areas that are considered high risk. For instance, autonomous haul trucks are able to traverse difficult terrain with accuracy, which results in more production as well as enhanced safety.

Improving the Surveillance of the Environment

Mining operations are required to adhere to stringent environmental regulations including the quality of the air, the amount of water used, the stability of the soil, and the treatment of waste. Through the use of satellite data and linked sensors, artificial intelligence is able to keep these parameters under constant surveillance. It is possible for systems to identify chemical pollution, movement on the ground, and the production of excessive amounts of dust. Companies are able to react promptly, steer clear of any transgressions, and ensure that their mining activities are sustainable because of this monitoring.

Improving the Effectiveness of Ore Sorting and Processing

Manual assessment or basic scanning are the two methods that are traditionally used for ore sorting, although both methods are often incorrect and slow. Utilizing optical, chemical, and density-based features, AI-powered sorting systems are able to distinguish between trash and high-grade ore with an impressive degree of accuracy. The process of sorting may be completed in a shorter amount of time and with more precision, which results in a higher yield of materials, a reduction in the time required for processing, and a decrease in the amount of energy that is used in activities farther downstream.

Decreasing the Amount of Fuel and Energy That Is Consumed

A significant quantity of both fuel and electricity is used by mining machines. Artificial intelligence is used to examine operating behavior, load cycles, topographical conditions, and driving patterns in order to maximize the efficiency of fuel use. Intelligent algorithms are able to decrease waste by adjusting the speed of the machine, the route selection, and the engine load. Operational expenses are lowered when fuel usage is reduced, and sustainability objectives are supported by this practice.

Keeping an Eye on the Structural Stability of Mining Operations

There are serious dangers associated with structure collapse when it comes to mining operations that take place below the surface. Artificial intelligence models use a combination of seismic data, rock stress measurements, and geological trends in order to make predictions about the possibility for alterations in rock formations. Engineers are able to take corrective steps, strengthen tunnels, or reroute activities in order to prevent a collapse from happening when instability is detected early on. Because of this skill to anticipate occurrences, lives are preserved and catastrophic interruptions to operations are averted.

Enhancing Both Air Quality and the Efficiency of Ventilation Systems

Toxic gasses, dust, and inadequate ventilation are all byproducts of mining that have the potential to negatively affect the health of miners. Artificial intelligence (AI) systems are capable of improving ventilation by means of altering fan speeds, controlling the direction of airflow, and detecting fluctuations in gas concentration. By providing air quality measurements in real time, analytics may help keep air quality below unsafe levels, hence decreasing the dangers of respiratory diseases and fostering more healthful work conditions.

Improving Haulage Operations and the Supply Chain

Through the effective routing of trucks, the prediction of loading times, and the optimization of dump placements, artificial intelligence (AI) is able to enhance the logistical operations that take place inside the mines. Traffic congestion is reduced, idle time is decreased, and the efficiency of ore transportation is increased when there is real-time coordination between equipment and transportation vehicles. This simplified flow helps to ensure that output remains consistent and predictable.

Minimizing Mistakes Made by People

Misjudgment, delayed responses, and misunderstanding are all factors that contribute to a large number of mining accidents. Operators are able to make precise and timely decisions more easily because to the real-time insights and warnings that are provided by artificial intelligence decision-support systems. The need on human guessing is reduced by these technologies, which also assist in maintaining uniformity throughout processes.

Making Decisions Based on Data for Those in Charge of Mining Operations

Data collection and analysis for a variety of activities, including drilling, blasting, transporting, processing, and environmental monitoring, are performed by AI platforms. Dashboards with clear visualizations and actionable data are provided to managers, which are beneficial in the optimization of shift plans, resource deployment, equipment utilization, and safety protocols. Operational efficiency and the accuracy of strategic planning are both improved as a result of this data-driven strategy.

Advancements That Will Be Made in the Future with Artificial Intelligence-Powered Mining

Mining in the future will include a number of new technologies, including the use of self-learning systems that are constantly enhancing the precision of operations, artificial intelligence-assisted geological modeling, totally autonomous fleets, and digital twins of whole mines. The use of these improvements will result in the establishment of mines that are more secure, use less energy, and are highly optimized.