Machine Learning Models for Predicting Machine Failures

Machine Learning Models for Predicting Machine Failures

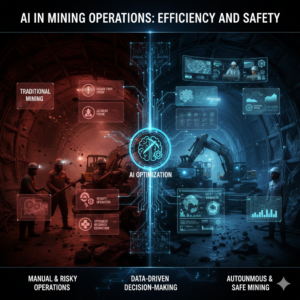

In contemporary companies that rely on the consistent and dependable functioning of their equipment, machine learning models for forecasting mechanical problems are becoming more important. Downtime, lost resources, and safety concerns were frequent outcomes of traditional maintenance techniques, which often depended on regular inspections or reactive repairs after a breakdown was occurred. By evaluating operating trends, sensor readings, and previous performance records, machine learning provides a proactive and data-driven strategy that enables it to foresee probable problems before they occur. This enables enterprises to transition from reactive maintenance to predictive maintenance, which extends the lifetime of equipment and maximizes output.

Utilizing Machine Learning to Develop an Understanding of Predictive Maintenance

Algorithms that are able to detect trends and abnormalities in the behavior of machines are used in predictive maintenance. The likelihood that a failure will occur at some point in the future is determined by the models, which assess data that has been collected from sensors, logs, and operational metrics. Over time, the models get more and more accurate as they are always learning from fresh data, which assists industry in preventing unforeseen failures and lowering the costs of maintenance.

Importance of Sensor Data When It Comes to Predicting Failures

There are a large number of sensors that are installed on industrial machinery in order to monitor various factors, such as temperature, vibration, pressure, noise, torque, and energy usage. This constant stream of information is analyzed by machine learning models, which are able to detect any instances when the data diverges from typical operating ranges. Even little alterations, such a tiny rise in the level of vibration or warmth, might be an indication that degradation is in its first stages. The remaining usable life of the components may be estimated by using these indications, and regions that need urgent care can be highlighted with the use of these indicators as well.

Leveraging Past Information for the Purpose of Training Models

The establishment of training prediction models is based on a combination of historical performance data, maintenance logs, prior breakdowns, and operating circumstances. Algorithms used in machine learning search for connections between specified patterns and known failure occurrences. The system has the ability to reliably forecast when a failure could occur in real-time operations by learning from this past dataset and recognizing patterns that are similar to those in the dataset. Due to the presence of this historical background, it is possible to create forecasts that are both more dependable and more accurate.

Frequently Used Methods in Machine Learning for the Forecasting of Failures

Depending on the complexity of the equipment and the kind of data that is accessible, a number of different machine learning approaches are used.

- It is possible to determine whether or not a component is in good condition and whether or not it is likely to fail in the near future by using classification algorithms.

- The remaining usable life of parts may be estimated using regression models.

- When trying to figure out when irregularities may appear, time-series forecasting takes a look at performance patterns over a period of time.

- The purpose of anomaly detection models is to identify atypical behavior that does not correspond to any previously recognized failure pattern but yet suggests the possibility of danger.

Automated Alerts and Real-Time Analysis

Systems that use machine learning run on a constant basis, taking in and analyzing sensor data in real time. The model gives rapid notifications to maintenance staff if it identifies any irregularities or anticipates a forthcoming malfunction. Before damage becomes more severe, these notifications assist operators in scheduling inspections, placing orders for replacement parts, or turning off machinery. The implementation of real-time analysis guarantees that preemptive measures will be performed as soon as they are feasible.

Uncovering Patterns of Failure That Are Not Apparent

There are several pieces of equipment that have minor, almost imperceptible symptoms that precede more serious problems. The process of machine learning is particularly adept at discovering these concealed patterns that are beyond the capability of people to detect via the use of manual monitoring. For example, an indication that there is misalignment, lubrication problems, or internal wear may be revealed by a little change in the frequency of vibration or a modest variation in the amount of power that is used. Catastrophic failures and the expenses associated with repairs are both minimized when these trends are detected early on.

Forecasting the Amount of Time that Components Have Left to be Used

One of the most significant uses of machine learning is the ability to forecast the amount of time that remains before essential components fail. The technology is able to determine the length of time that a component will be able to operate safely by doing an analysis of degradation patterns. Industries are able to arrange replacement parts at the most advantageous moments by using this method, so preventing both unexpected failures and premature alterations. The use of accurate life forecast contributes to the reduction of waste and the enhancement of resource planning.

Making Maintenance Schedules More Efficient

Industries have the ability to modify their maintenance plans based on the real status of their machines rather of relying on guessing, when they are able to make accurate forecasts. By eliminating superfluous regular tests while also guaranteeing that components are maintained or replaced precisely when they are required, predictive maintenance is a useful tool. This decreases the labor associated with maintenance, lowers the amount of time that is lost due to equipment failure, and maintains the operation of machinery at its most efficient level.

Making Industrial Operations Safer

Especially in heavy industries, the breakdown of machinery may result in major safety risks. Early detection of problems and the implementation of preventative measures are made possible via the use of machine learning models, which aid in the avoidance of hazardous circumstances. Before any accidents may occur as a result of defective equipment, the machinery can be turned off, therefore minimizing the danger posed to employees and safeguarding the facility from any harm to its structure or operations.

Cutting Down on Expenses and Increasing the Effectiveness of Operations to the Greatest Degree Possible

The use of predictive machine failure models leads to a substantial decrease in operating expenses as a result of their ability to avoid costly malfunctions, minimize the amount of time that machines are not functioning, and optimize the distribution of manpower. When it is absolutely required to do so, ordering replacement components helps to make the spare parts inventory more manageable. Additionally, energy consumption is reduced as a result of the fact that equipment that are well maintained are more efficient.

Ongoing Education and Refinements to the Model

Over the course of time, machine learning models develop as they get fresh data from equipment. Each fresh cycle of analysis assists in making forecasts more accurate and improving the level of precision. The system is able to adapt to changes in machine behavior, ambient circumstances, or operational procedures by continuously learning. As more data becomes accessible, the accuracy and dependability of forecasts continue to improve.

Combining Machine Learning Models with Industrial Internet of Things Systems

When industrial Internet of Things (IoT) networks are connected to machine learning systems, the whole ecosystem of predictive maintenance becomes automated. The data that is collected by the sensors is sent directly into machine learning platforms, which analyze insights and interact with maintenance systems or operators. The workflow that is created by this integration is very well-coordinated, and the choices that are made are based on information that is provided in real time.

Modeling Predictive Failure for the Future

The future will entail the development of increasingly sophisticated models that incorporate elements of deep learning, digital twins, and complex simulations. The use of these technologies will enable companies to put hypothetical situations to the test, get a more in-depth understanding of the reasons for failures, and achieve near-zero unplanned downtime. Predictive failure analysis will eventually become a common component of all industrial operations as artificial intelligence continues to be developed.