Predictive Models for Industrial Equipment Lifespan

Predictive Models for Industrial Equipment Lifespan

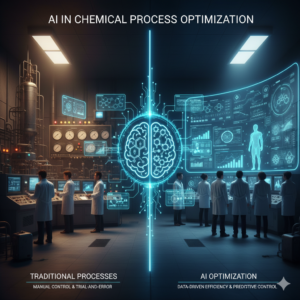

By making precise predictions about the length of time that gear will remain in use and by recognizing possible malfunctions prior to their occurrence, predictive models are revolutionizing the way that businesses handle equipment. Conventional maintenance strategies often result in unexpected downtime, expensive breakdowns, and the inefficient use of resources because they depend on predetermined timetables or fixes that are implemented in response to problems. Artificial intelligence (AI) powered predictive modeling makes this possible by examining performance data in real time, environmental variables, and historical patterns, in order to make highly accurate predictions about the status of the equipment. This enables enterprises to make preventive maintenance plans, increase the lifespan of their gear, and boost overall production while simultaneously minimizing the hazards associated with operations.

Monitoring Conditions in Real Time

Artificial intelligence systems are able to keep a constant eye on things like the degrees of vibration, the temperature, the pressure, the noise, and the electrical load. The model is able to detect any of the early indicators of wear or failure as soon as a parameter starts to deviate from its usual range.

Analysis of Past Data

Years’ worth of maintenance logs, failure histories, and operating trends are all examined by predictive models. This makes it possible to determine the precise circumstances that usually mark the beginning of a reduction in the performance of equipment.

Making Non-Obvious Deterioration Apparent

There are some kinds of equipment deterioration that cannot be seen by the human eye or identified via routine inspections. Artificial intelligence is able to recognize these minute changes by using pattern recognition and sophisticated analytics.

Forecast for the Remaining Useful Life (RUL)

Estimating the amount of time that will pass before a component malfunctions is one of the most beneficial attributes that predictive modeling has. This assists maintenance workers in the planning of replacements and in preventing failures that occur without warning.

More Effective Maintenance Scheduling

Maintenance that is performed at precisely the right moment is recommended by artificial intelligence rather than maintenance that is performed at predetermined times. As a result, this guarantees that equipment will not be maintained either prematurely or beyond the due date, which conserves both time and resources.

Decreasing An Unanticipated Period of Inactivity

By providing predictive insights, companies are able to resolve problems before they become major failures that need intervention. As a result, disruptions in production are kept to a minimum, and overall operational dependability is enhanced.

Optimizing the Cost

Companies may make plans about their budgets, buy replacement components ahead of time, and avoid spending money on emergency repairs when they have access to precise projections about the lifetime of their equipment. As a result of this, the allocation of resources becomes more efficient.

Feedback on the Improved Equipment Design

The engineering of new equipment may be enhanced by manufacturers that make use of predictive insights. It will be possible to create more durable designs in the future if the components that fail first are understood.

Incorporation of Internet of Things Detectors

Artificial intelligence models are provided with constant input from Internet of Things sensors, which allows for the real-time monitoring of machine stress, ambient conditions, and performance deviance. The accuracy of predictions is increased as a result of this integration.

Finding out how the surroundings are affected

The life of equipment may be reduced by factors such as heat, humidity, dust, and the vibrations that emanate from nearby machinery. The artificial intelligence assesses these external variables and determines the extent to which they have an impact on long-term performance.

Giving precedence to high-risk machines

Predictive models evaluate equipment based on the likelihood of failure when it comes to managing huge industrial fleets. It will therefore be possible for the maintenance crews to concentrate their efforts on the most important machinery.

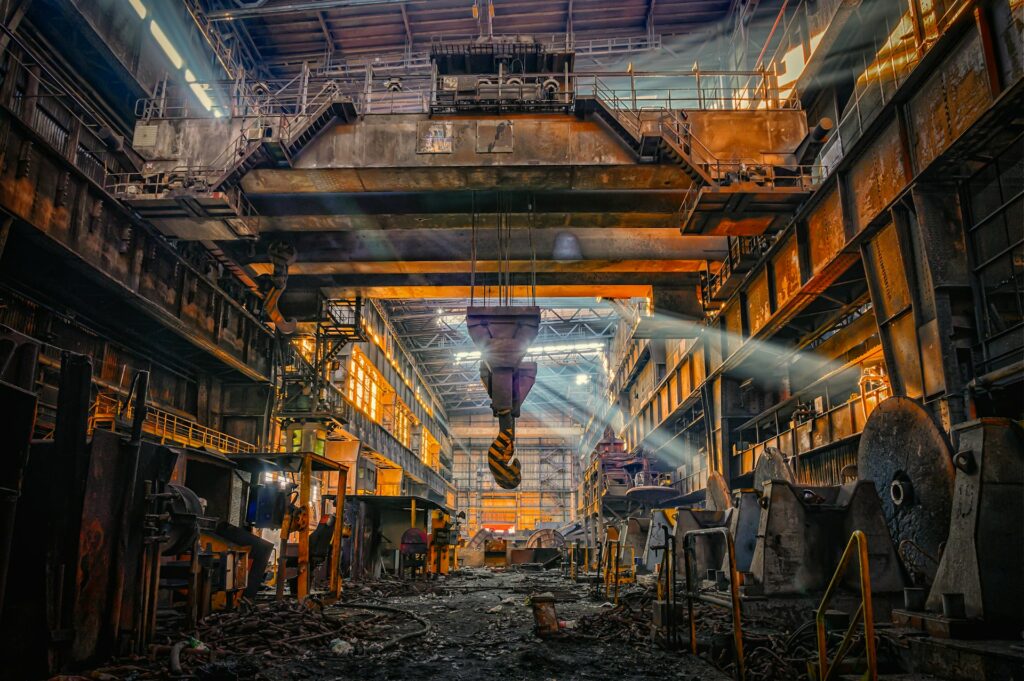

Reducing the Dangers to Safety to the Lowest Possible Level

When equipment fails, it may result in hazardous conditions, particularly in environments like manufacturing facilities, oil refineries, and power plants. Teams are able to prevent these types of dangers because predictive modeling generates warnings prior to the occurrence of a dangerous breakdown.

Enhancing operational efficiency

When there are fewer unexpected breakdowns, the operation of factories runs more smoothly. The accuracy of production planning is increased, and overall productivity gains are realized.

Extending the Lifecycle by Means of Optimized Utilization

Artificial intelligence suggests the best operating conditions for minimizing the load placed on equipment. When equipment is used under optimal conditions, it will last longer in general.