AI in Aerospace Component Quality Assurance

AI in Aerospace Component Quality Assurance

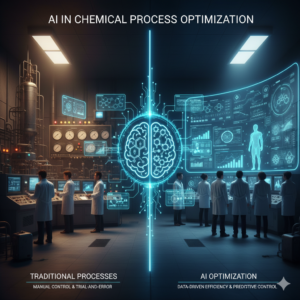

Aerospace manufacturers are using artificial intelligence in order to change the way in which they check, assess, and certify the many components that are used in airplanes. Because even minor flaws have the potential to jeopardize safety, aerospace components must adhere to the most stringent criteria for dependability and accuracy. Heavy reliance on manual inspections, time-consuming assessments, and several levels of testing are the foundations of traditional inspection systems. The use of artificial intelligence in these procedures improves them by offering more rapid analysis, a higher degree of accuracy, and ongoing monitoring throughout the various phases of production. Aerospace quality assurance is undergoing a transformation that is making it more efficient, consistent, and in line with contemporary safety standards by means of machine learning, computer vision, and predictive modeling.

Computer-automated visual inspection (AVI)

The components are scrutinized for minuscule fractures, misalignments, and irregularities on their surfaces using computer vision systems that are driven by artificial intelligence. When compared to human inspections, these technologies are able to discover flaws with more accuracy and speed, therefore guaranteeing that each component adheres to the stringent criteria for quality in the aerospace industry.

Testing that has been Improved and is Non-Destructive

Aerospace components often undergo non-destructive testing techniques, which might include ultrasonic, thermal, or X-ray examination. Artificial intelligence is able to analyze these intricate data patterns in order to discover latent defects that might potentially go unnoticed during human examination.

Monitoring the Production Line in Real Time

Artificial intelligence keeps an eye on a variety of phases in the production process and makes sure that every single material, dimension, and tolerance stays within the specified limits. The generation of immediate notifications prevents batches that are faulty from continuing.

Analysis of Predictive Quality

In order to determine when problems are likely to occur, machine learning algorithms assess data from previous production runs. Engineers are able to avert problems before they occur as a result of this, which enhances consistency and lowers the amount of waste generated.

Validation of the Material’s Integrity

The aircraft manufacturing industry depends on the use of metals and composite materials. In order to confirm that they are strong, long-lasting, and capable of performing well in severe environments, artificial intelligence investigates their microstructures.

Precision Verification and Automated Measurement

By comparing components to precise digital models, artificial intelligence techniques guarantee that the size, thickness, and shape of the components correspond to the necessary criteria. This decreases the likelihood of human mistake and increases the capacity to replicate results.

Enhanced oversight of the supply chain’s quality

Components for aerospace may originate from a variety of different sources. In order to guarantee that incoming components meet the same stringent quality criteria, artificial intelligence (AI) assesses supplier data, delivery trends, and previous performance.

Process optimization has been improved.

Artificial intelligence is able to recognize which machining, assembly, or finishing operations are inefficient. Defects are reduced and total manufacturing speed is improved by optimizing these stages, without losing quality.

Early Detection of Both Fatigue and Material Wear

Artificial intelligence models are able to identify the early indicators of structural deficiencies, corrosion, or metal fatigue. The long-term dependability of aircraft is guaranteed and the maintenance expenses for aircraft makers are reduced when these problems are identified at an early stage.

Shortening the Duration of Inspections

By automating repetitious operations and processing data at a pace that surpasses that of human inspectors, artificial intelligence expedites the quality assurance process. This improvement in efficiency of manufacturing is achieved while still adhering to all regulations.

Maintaining Adherence to Standards Established by the Industry

There are stringent safety rules that the aerospace manufacturing industry must adhere to. Artificial intelligence facilitates the documentation of inspection outcomes, ensures traceability, and generates compliance reports in a more efficient manner.

Incorporation With Digital Twins

The purpose of digital twins is to imitate the way that components operate in real-world settings. Artificial intelligence improves these simulations by detecting possible failure areas and refining the design of parts to increase their dependability.

Enhancing the Safety of Employees

Technicians are less likely to be required to do risky manual assessments, particularly in locations that are hazardous or while handling heavy equipment, as a result of the automation of hazardous inspection activities by artificial intelligence.

An ongoing cycle of quality feedback

Artificial intelligence offers constant insights that assist engineers in refining the parameters of production and in selecting the appropriate materials. As a result of this, an ongoing cycle of improvement is established, which in turn raises the overall quality of aerospace components.