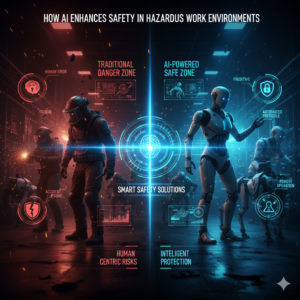

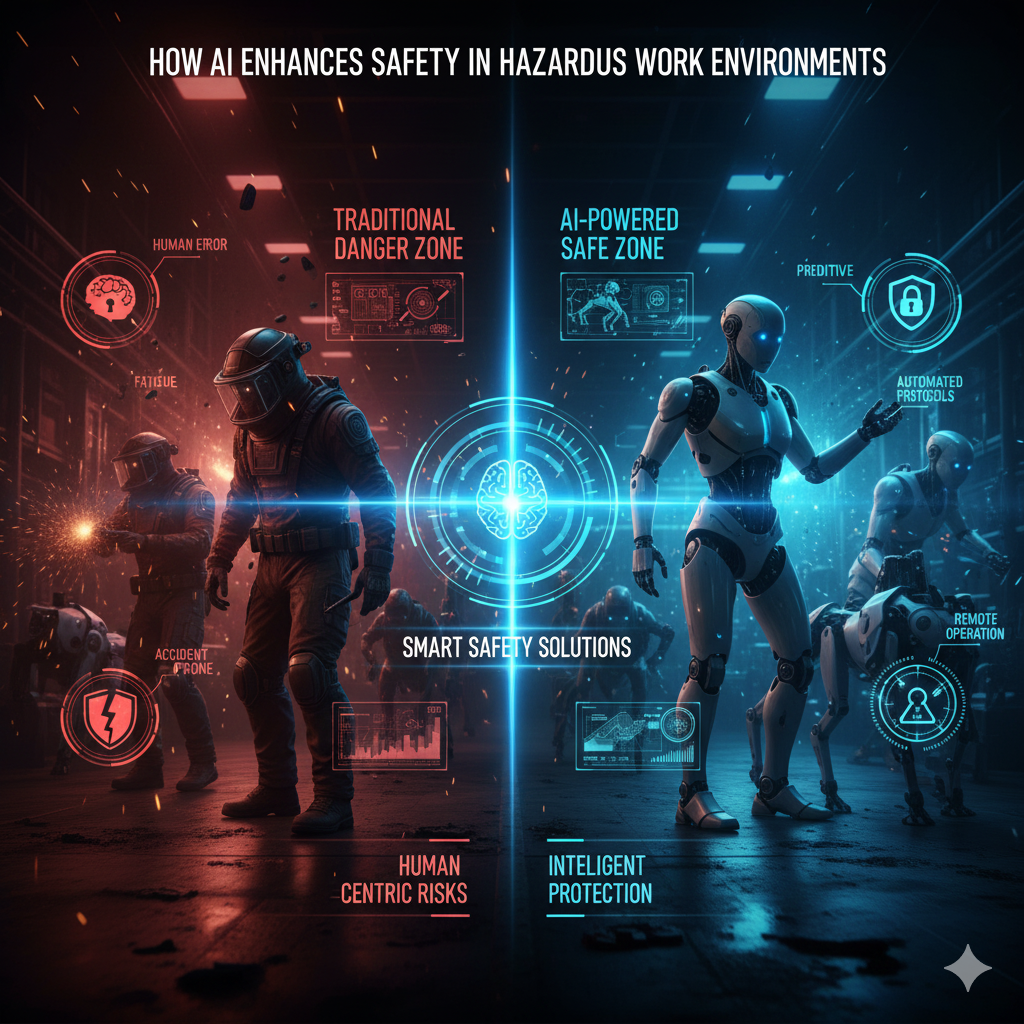

How AI Enhances Safety in Hazardous Work Environments

How AI Enhances Safety in Hazardous Work Environments

In businesses that entail dangerous surroundings, such as the oil and gas industry, chemical processing, building, mining, and heavy manufacturing, safety in the workplace is a major issue. Even while traditional safety precautions, such as doing safety drills, wearing protective gear, and performing manual inspections, are necessary, they are often inadequate in preventing accidents from occurring. Artificial Intelligence (AI) is becoming an increasingly effective tool for improving safety by allowing for the monitoring of situations in real time, the prediction of potential hazards, and the facilitation of proactive responses.

Environments That Are Dangerous to Work in: The Difficulties of the Situation

Working in dangerous conditions poses a continual threat to employees, who are at risk of being exposed to poisonous substances, severe temperatures, heavy equipment, systems with high pressure, and structural breakdowns. The occurrence of accidents and injuries in the workplace may be attributed to a number of factors, including human mistake, delayed discovery of harmful situations, and the absence of real-time monitoring. Consistent safety must be guaranteed, and in order to do this, constant monitoring is necessary. It might be challenging to achieve this just via the use of traditional procedures.

Systems for Monitoring Powered by Artificial Intelligence

Artificial intelligence contributes to the improvement of safety in the workplace by making it possible to monitor dangerous circumstances in real time. Data on a variety of factors, including temperature, air quality, machine functioning, worker position, and environmental risks, are gathered by sensors, cameras, and wearable devices. Anomalies, dangerous actions, and deviations from established safety measures are all identified by artificial intelligence algorithms that examine this data. It is possible to send notifications to employees and managers instantaneously, which enables the implementation of quick remedial measures.

Estimation of Potential Future Risks

Artificial intelligence does not only react to threats that are imminent; it anticipates possible risks before they become more serious. The purpose of using machine learning models is to examine previous event data, equipment performance metrics, and environmental conditions in order to discover trends that may result in accidents. Companies are able to adopt preventative actions, such as equipment maintenance, workflow improvements, or personnel training, via the use of predictive risk assessment, which in turn reduces the probability of accidents occurring.

Improving the level of protection provided to workers

Smart helmets, vests, and wristbands are examples of wearable artificial intelligence systems that track the movements and vital signs of employees in real time. Artificial intelligence is capable of detecting whether someone is fatigued, has an abnormal heart rate, has been exposed to toxic gasses, or is in close proximity to equipment that might cause injury. Employees are able to take preventative measures and enhance the general safety of dangerous areas by receiving warnings and suggestions from these systems.

Automation for Hazardous Work

Dangerous jobs that might ordinarily put human workers in danger may be carried out by automated systems and AI-driven robots. Artificial intelligence-controlled drones, for instance, are capable of inspecting high buildings, autonomous vehicles are able to deliver hazardous products, and robotic arms are able to manage dangerous compounds. The use of artificial intelligence (AI) may greatly decrease the likelihood of accidents occurring in the workplace by limiting the amount of direct human involvement.

Crisis Intervention and Decision-Making Assistance

In the case that an incident were to occur, artificial intelligence may assist emergency response teams by evaluating data that has been collected from surveillance systems and sensors. It is capable of recognizing the most secure evacuation routes, arranging response activities in order of importance, and supplying safety personnel with an understanding of the situation. Artificial intelligence (AI)-powered simulations and prediction models are also of assistance to companies in their preparation for possible crises and the optimization of safety practices.

Integration with the Internet of Things (IoT) and smart facilities

Artificial intelligence, when used in conjunction with smart facility systems and the Internet of Things, creates a fully linked safety environment. A centralized artificial intelligence platform is capable of incorporating real-time data that is gathered from wearable devices, environmental sensors, and machines. This allows for the constant surveillance, predictive upkeep, and intelligent safety administration that guarantees that risks are dealt with before they pose a harm to employees.

Workplace Safety and the Role of Artificial Intelligence in the Future

The function of artificial intelligence technology in hazardous work situations will increase as the technology continues to progress. It is possible that more improved computer vision, cutting-edge robotics, and autonomous monitoring may be included into future systems in order to anticipate and avoid accidents with a higher degree of accuracy. By implementing AI-powered safety measures, organizations will see a reduction in the number of injuries, a decrease in insurance premiums, an increase in compliance, and the development of a more secure and efficient workforce.

Artificial intelligence is bringing about a transformation in the safety of the workplace by integrating real-time monitoring, predictive analytics, and automation. In surroundings that pose a threat to human life, artificial intelligence not only protects workers from present hazards but also forecasts potential threats, which allows for preemptive actions that save lives, lessen injuries, and improve the efficiency of operations.