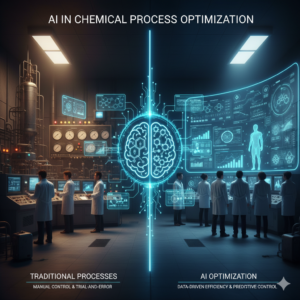

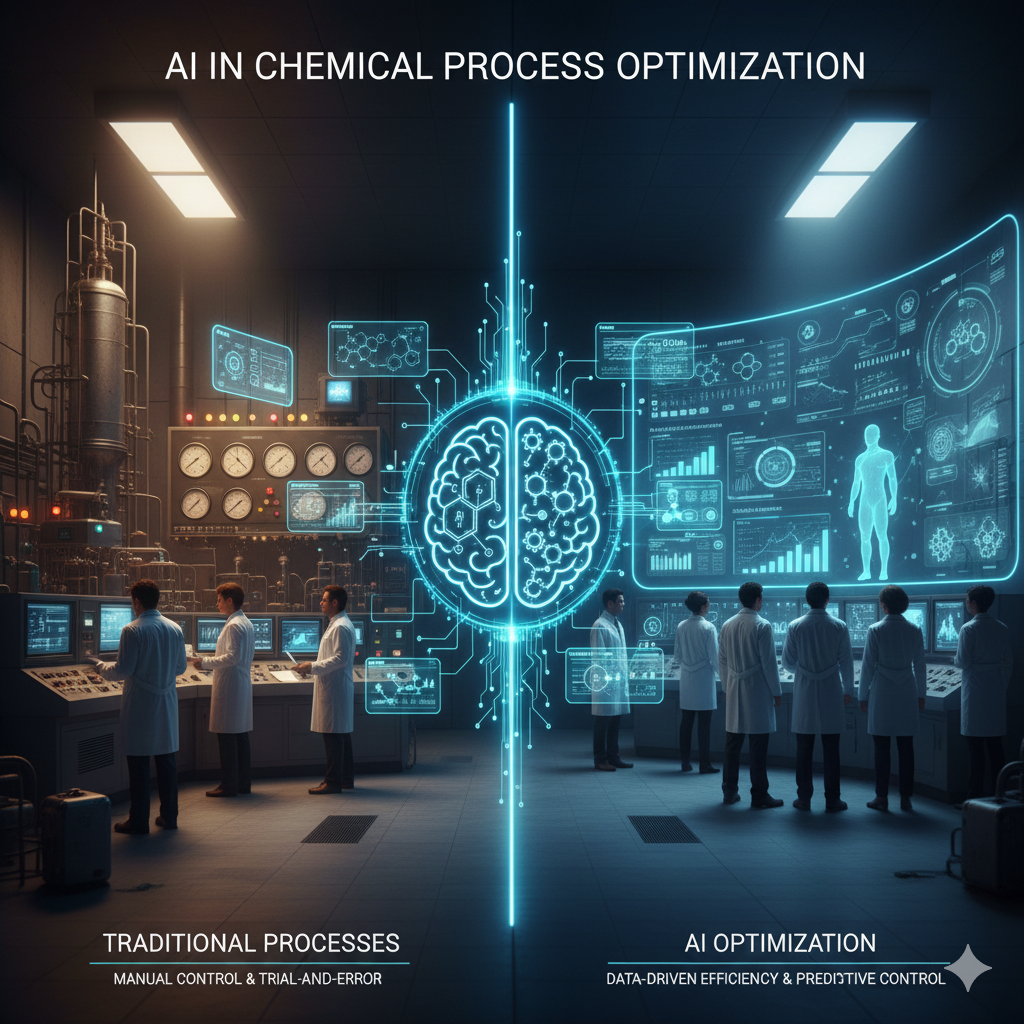

AI in Chemical Process Optimization

AI in Chemical Process Optimization

The operation of chemical plants is undergoing a transformation as a result of artificial intelligence, which is taking complicated, data-intensive processes and translating them into workflows that are highly optimized, efficient, and predictable. In the course of the chemical manufacturing process, it is common for there to be ongoing reactions, fluctuations in temperature, extreme pressure, and a variety of raw materials that react in various ways when the circumstances are altered. Artificial intelligence assists companies in improving the accuracy of their control over these factors, decreasing the amount of waste produced, enhancing the consistency of their products, and increasing safety. Intelligent algorithms are able to identify deviations before they happen, suggest ways to remedy them, and fine-tune processes without stopping production when they are provided with real-time data processing. Chemical producers are now able to run their businesses at a reduced cost while still adhering to more stringent quality and sustainability criteria because to this transition toward artificial intelligence-driven process optimization.

Monitoring the Process in Real Time

Artificial intelligence systems are used to monitor chemical processes that are currently taking place by analyzing data that has been collected from sensors, reactors, and equipment. Rather of depending only on human inspections, the plants are provided with constant and precise information about the temperature, pressure, and material flow. As a result of this, more consistent production cycles and quicker adjustments are achieved.

Making Predictions Based on Reaction Behavior Models

Models that use machine learning are used to investigate the behavior of chemicals under a variety of various process circumstances. Engineers may use these predictions to modify factors such as the concentration of the catalyst or the amount of time allotted for the reaction, therefore enhancing the amount of product generated and reducing the amount of by-products.

Decreasing the Amount of Unused Raw Materials

Artificial intelligence is able to detect any inefficiencies in the mixing, heating, or dosing of raw ingredients. Chemical factories are able to considerably reduce the amount of wasted material and decrease their operating expenses without sacrificing the quality of their products by optimizing these factors.

Quality Control that is Automated

Artificial intelligence (AI) is able to identify small variations in the composition or color of a product that might be indicative of a quality problem by using pattern recognition. Defective batches are reduced to a minimum and product consistency is maintained at a high level thanks to the use of automated decision-making.

Otimização do Desempenho do Equipamento

Utilizing artificial intelligence, symptoms of wear or irregular operation are detected via the analysis of equipment use patterns. This improves the scheduling of maintenance activities to be carried out at the appropriate time, minimizes equipment failures, and enhances the dependability of reactors, pumps, and distillation systems over the long run.

Advancements in Energy Efficiency

In chemical facilities, boilers, distillation columns, and heat exchangers are among the most significant users of energy. The whole facility is able to be more energy-efficient and cost-effective as a result of the artificial intelligence’s ability to make real-time adjustments to energy consumption in accordance with demand.

More Secure Process Operations

In the event that hazardous circumstances emerge, AI systems are able to detect them. These potentially dangerous situations include abrupt increases in temperature, improper chemical dosage, and gas leaks. Artificial intelligence (AI) is able to assist in the reduction of accidents and the protection of employees by sending out quick notifications or by starting automatic shutdowns.

Improving the Efficiency of Batch and Continuous Manufacturing Processes

Artificial intelligence (AI) is used to optimize cycle durations and ingredient ratios in batch operations. It guarantees that flows are stable and that response conditions are constant in processes that are continuous in nature. The outcome of both approaches is a greater rate of throughput and a reduced rate of variability.

Increased Catalyst Effectiveness

In the process of chemical reactions, catalysts are an essential component. Artificial intelligence may be used to make predictions about when a catalyst will deteriorate or how it might be utilized in a more effective manner, which will lead to faster response rates and cheaper running costs.

Industrial Internet of Things Integration

The combination of artificial intelligence with Internet of Things sensors results in a much more powerful technology. By establishing a connection between data originating from a number of different units, it is able to anticipate malfunctions, enhance the allocation of resources, and guarantee that all of the equipment is operating in synchronization with one another in order to maximize production.

Process Control That Is Adaptive

The artificial intelligence (AI) system makes automated adjustments to parameters like pH, viscosity, or temperature depending on the current circumstances. The provision of a more reliable and optimal production environment is accomplished via the use of this continuous feedback loop.

Methods for Creating Chemicals in an Environmentally Friendly Way

Artificial intelligence assists in the reduction of emissions by optimizing chemical recycling, increasing combustion efficiency, and locating more environmentally friendly industrial routes. This lends support to the aims of sustainable development on a global scale as well as to the criteria for cleaner production.

Expedited Troubleshooting and Root Cause Analysis

AI is capable of rapidly determining the underlying reason for a process variation by examining previous trends. This reduces the amount of time that it takes to troubleshoot and also reduces the amount of time that is wasted due to downtime.

Enhanced development of the product

Chemists are able to use AI simulations to conduct virtual tests of the outcomes of reactions before they actually do real experiments. This results in a reduction in the time spent on research and development, a decrease in the expenditures associated with testing, and a more rapid production of novel chemical products.