How AI Monitors Water Usage in Industrial Plants

How AI Monitors Water Usage in Industrial Plants

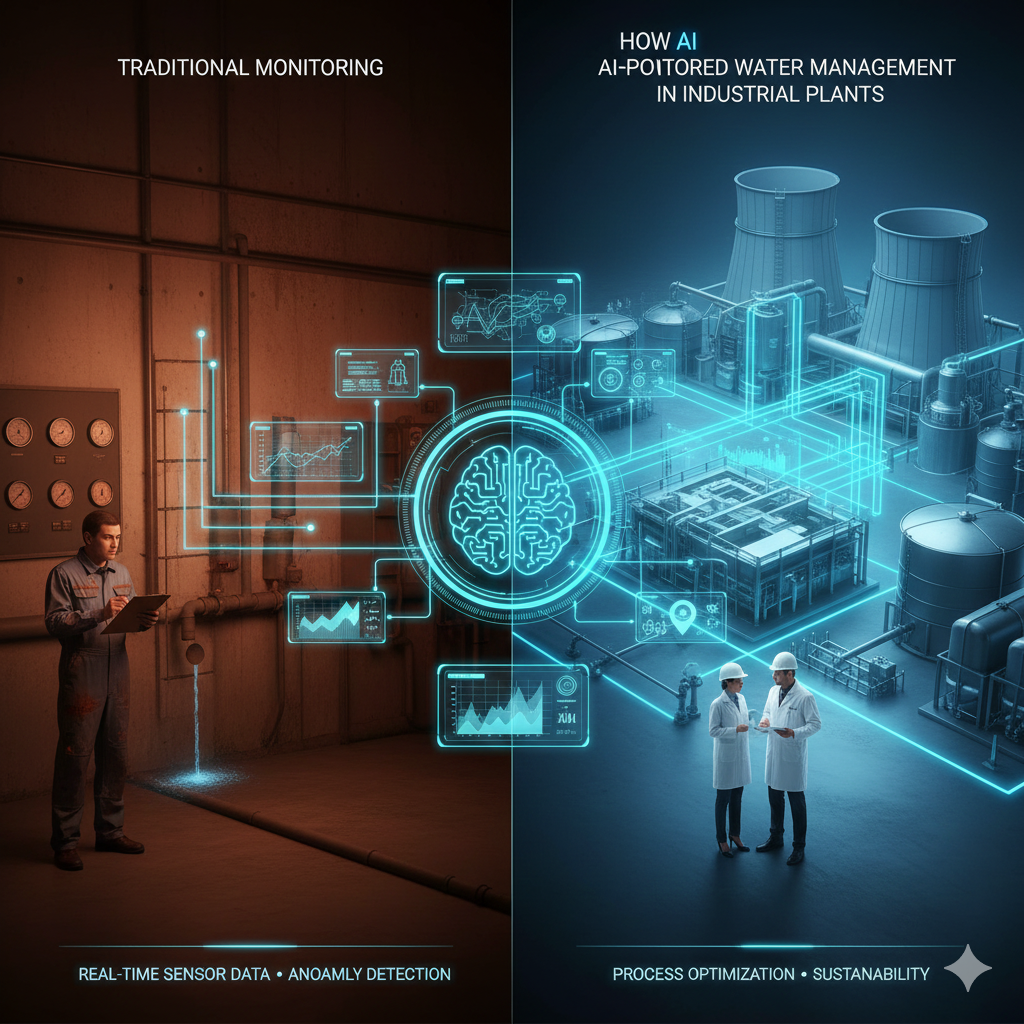

The use of artificial intelligence to keep track of water consumption in industrial facilities marks a significant advancement in the direction of more intelligent resource management, improved operational efficiency, and a greater sense of environmental responsibility. Although industries are dependent on water for processes such as cooling, processing, cleaning, and chemical reactions, the conventional methods of monitoring these processes sometimes include human inspections, readings from fixed meters, and delayed reporting. With the use of artificial intelligence, this antiquated system is transformed into a real-time, automated, and predictive framework that enables enterprises to minimize waste, eliminate leaks, and maintain compliance with regulations while simultaneously reducing their operating expenses.

Real-Time Surveillance Utilizing Intelligent Sensors

In order to constantly collect information on the rates of flow, the temperature, the pressure, and the amount of water being used, AI-enabled sensors have been installed in a variety of locations, including pipelines, tanks, boilers, cooling towers, and processing units. The visibility of water consumption on a second-by-second basis is provided by these sensors, which is in contrast to periodic manual readings. The data that has been gathered is sent to artificial intelligence systems, which evaluate patterns of consumption, identify abnormalities, and point out regions where water is being utilized in excess. It is possible to avoid wasteful and inefficient operations from developing into expensive and serious problems by using real-time monitoring.

Identifying Leaks and Irregular Usage Patterns

In industrial buildings, water leakage often stays undetected for an extended period of time, ranging from days to even weeks, resulting in substantial losses. Abnormal variations in pressure or flow are detected in an instant by artificial intelligence algorithms that examine data from sensors. The moment that patterns that are not typical occur, the system triggers notifications, enabling maintenance personnel to address the situation right away. Water loss is prevented, equipment is protected from damage, and the amount of downtime that goes unnoticed due to leaks is decreased, all as a result of this early detection.

Conduct a predictive analysis on the demand for water.

The amount of water used by industrial facilities is influenced by a number of factors, including production cycles, environmental conditions, and the operation of the equipment. As a result, water consumption varies. Artificial intelligence (AI) creates predictive models that anticipate the amount of water that will be needed hours, days, or even weeks in advance. Operators are able to make preparations for water reserves, plan out processing activities, and minimize the needless extraction of water with the assistance of these predictions. The implementation of predictive use planning guarantees that facilities are able to continue their operations without exceeding the capacity of their water infrastructure.

Improving the Efficiency of Cooling Tower and Boiler Operations

Boilers and cooling towers are two of the industrial plant components that use the most water. Artificial intelligence is used to assess data like fluctuations in temperature, rates of evaporation, and system load in order to optimize water cycles. It is capable of regulating the pace at which water is fed, preserving optimal chemical balances, and preventing excessive blowdown or evaporation. These improvements decrease the amount of water that is wasted and enhance energy efficiency, which in turn leads to lower costs and greater environmental sustainability.

Systems for Water Recycling and Reuse That Are Automated

Reverse osmosis, chemical treatment, and filtration are just a few of the methods that are used by several businesses to recycle water. Artificial intelligence improves these recycling processes via the monitoring of water quality, the adjustment of treatment levels, and the prediction of when filters or membranes need repair. Recycled water is guaranteed to constantly fulfill quality criteria and to decrease the usage of fresh water sources using artificial intelligence (AI) via the automation of these choices. This results in the more effective conservation of resources and the more efficient distribution of those resources over the long run.

Keeping an Eye on Water Quality at the Facility

In order to ensure the integrity of water quality, artificial intelligence (AI) systems perform analyses on many parameters, including pH, turbidity, conductivity, pollution levels, and dissolved oxygen. As a result of the implementation of real-time quality control measures, operators are now able to identify the presence of contamination, chemical imbalances, or violations from compliance norms. Rather of depending on sporadic laboratory examinations, factories have the ability to carry out continuous monitoring and intervene in quality concerns prior to the time when they impact equipment or finished goods.

Decreasing Expenditures on Operations by Utilizing Effective Water Management

Artificial intelligence (AI) assists industrial operations in decreasing excessive water bills, lowering energy use in water-related equipment, and reducing expenses connected with wastewater treatment by finding inefficiencies and optimizing consumption. Automated monitoring decreases the need for human inspections, while predictive models reduce the number of emergency repairs and unexpected downtime. These reductions have a substantial positive impact on the plant’s operating budget as time goes on.

Backing Up Compliance with Environmental Regulations

Industries are required to comply with stringent restrictions that govern both the amount of water they use and the amount of effluent they dump. Artificial intelligence solutions are capable of automatically monitoring compliance data, generating reports, and identifying areas that need attention. This helps to limit the possibility of incurring fines and guarantees that activities are conducted within the parameters that have been established. The various sectors are also able to show that they are accountable for their environmental actions by ensuring that their data is public.

Incorporating Artificial Intelligence into Industrial Internet of Things Architecture

The integration of artificial intelligence and Internet of Things devices results in the creation of an ecosystem for water management that is completely linked. The operations of pumps, valves, treatment equipment, and recycling units may be automatically adjusted in accordance with insights derived by artificial intelligence. By decreasing delays caused by human decision-making and enhancing coordination, this integration guarantees that the facility as a whole will remain in synchronization.

The Improvement of Sustainability Objectives in Contemporary Industries

The problem of water shortage is becoming more and more pressing, and businesses are under more pressure to minimize their impact on the environment. The objectives of sustainability are directly supported by artificial intelligence-driven water monitoring, which reduces consumption, improves recycling rates, and decreases the amount of pollution. The use of data-driven decision-making allows for the measurement of progress made by companies and the enhancement of their environmental strategies for the long run.

Progress That Is to Come in the Field of Artificial Intelligence-Based Water Management

The use of artificial intelligence (AI) to examine pipes, the implementation of autonomous water management systems, and enhanced predictive models that are referred to as “digital twins” will all be involved in the next wave of innovation. Because of these advancements, plants will be able to test water strategies in a simulated environment, implement conservation approaches with more accuracy, and get close to eliminating water waste.